Inconel® MetalsAlloys Specifications

Applicable Specifications for various Inconel® Alloys and Inconel® Metals:

AMS 5540

Description: The AMS 5540 specification covers a heat-resistant and corrosion nickel alloy in the form of plate, sheet and strip.

Material Specification: Nickel Alloy, Corrosion and Heat-Resistant, Sheet, Strip, and Plate, 74Ni – 15.5Cr – 8.0Fe, Annealed. You can find the AMS 5540 specification in Inconel® 600 Strip Alloy

AMS 5542

Description: The AMS 5542 specification is used for heat-resistant and corrosion nickel alloy in sheet, plate, and strip.

Material Specification: Nickel alloy sheet, strip, and plate with corrosion and heat resistance. Contains 72% nickel, 15.5% chromium, 0.95% niobium, 2.5% titanium, 0.70% aluminum, and 7.0% iron. It is annealed. You can find the AMS 5542 specification in the Inconel® X750 alloy strip

AMS 5596

Description: For products that are normally used in parts that require oxidation resistance up to temperatures of 1800 degrees F (982 degrees C), and creep and stress- rupture up to 1300 degrees F (704 degrees C). The AMS 5596 specification is great for parts that are welded or formed, and then heat treated in order to develop certain properties. It is not limited to these applications, however.

Material Specification: Nickel Alloy, Heat and Corrosion Resistant, Vacuum Induction or Consumable Electrode Melted, Solution Heat Treated 1775 degrees F (968 degrees C), 52.5Ni – 19Cr – 3.0Mo – 5.1Cb – 0.90Ti – 0.50Al – 18Fe. The AMS 5596 specification is commonly found in the Inconel® 718 strip alloy.

AMS 5597

Description: A heat and corrosion resistant nickel alloy, the AMS 5597 specification can be found in plate, strip, and wire. Most often, these products are used for parts in duct work. In times that require high strength when exposed to cryogenic temperatures and short time use in at a maximum of 1000 degrees F (538 degrees C). Parts that are welded or formed and subsequently heat treated to develop certain properties work well with this specification. But it is not limited to those treatments.

Material Specification: Heat and Corrosion Resistant, Nickel Alloy, Plate, Sheet, and Strip, Vacuum Induction or Consumable Electrode Melted, Solution Heat Treated 1950 degrees F (1066 degrees C), 52.5Ni – 19Cr – 3.0Mo – 5.1Cb (Nb) – 0.90Ti – 0.50Al – 18Fe. The AMS 5597 specifications is used in the Inconel® 718 strip alloy.

AMS 5598

Description: The AMS 5598 specification covers heat and corrosion resistant nickel alloys in strip, sheet, and plate procured in inch/pound units.

Material Specification: Nickel Alloy, Heat and Corrosion Resistant, Strip, Sheet, and Plate, Vacuum Induction, Remelted, or Consumable Electrode Melted, Precipitation Hardenable, Solution Heat Treated, 72Ni – 15.5Cr – 0.95 (Cb (Nb) + Ta) – 2.5Ti – 0.70Al – 7.0Fe. The AMS 5598 specification can be found in the Inconel® x750 strip alloy.

AMS 5599

Description: The AMS 5599 specification covers a nickel alloy that is both heat and corrosion resistant and takes the form of strip, sheet, and plate that is procured in inch/pound units.

Material Specification: Nickel Alloy, Heat and Corrosion Resistant, Strip, Sheet, Plate, Solution Heat Treated, 62Ni – 21.5Cr – 9.0Mo – 3.7Cb (Nb). AMS 5599 is a specification that is used mostly for the Inconel® 625 strip alloy.

AMS 5662

Description: The AMS 5662 specification covers a nickel alloy and is heat and corrosion resistant. It can be found in the form of flash welded rings, bars, forgings, and stock for forging flash welded rings or heading. It is used for parts that need high resistance to stress rupture and creep up to 1300 degrees F (704 degrees C) and oxidation resistance up to 1800 degrees F (982 degrees C), this is especially true for parts that are welded or formed and then precipitation heat treated in order to develop certain properties, however it is not limited to this application.

Material Specification: Precipitation Hardenable, Solution Heat Treated, Nickel Alloy, Heat and Corrosion Resistance, Bars, Rings, and Forgings, 52.5Ni – 19Cr – 3.0Mo – 5.1Cb – 0.90Ti – 0.50Al – 18Fe. The AMS 5662 specification can be found in the Inconel® 718 wire alloy.

AMS 5663

Description: Covering a nickel alloy, the AMS 5663 specification is heat and corrosion resistant and can take the form of flash welded rings, bars, forgings, and stock for forging or flash welded rings. They are normally used in parts that require high resistance to stress rupture and creep up to 1300 degrees F (704 degrees C) and oxidation resistance up to 1800 degrees F (982 degrees C), but it is not limited to these kinds of applications.

Material Specification: Nickel Alloy, Heat and Corrosion Resistant, Rings, Bars, Forgings, Vacuum Induction and Consumable Electrode Melted 1775 degrees F (968 degrees C), Precipitation and Solution Heat Treated, 52.5Ni – 19Cr – 3.0Mo – 5.1Cb – 0.90Ti – 0.50Al – 19Fe. The AMS 5663 specification is normally found in Inconel® 718 wire alloy.

AMS 5664

Description: The AMS 5664 specification covers a heat and corrosion resistant nickel alloy and is found in the form of flash welded rings, bars, forgings, and stock for forging or flash welded rings. It is most often found in rotating and structural parts that require high strength at cryogenic temperatures and for services over the short time at temperatures up to 1000 degrees F (538 degrees C) and oxidation resistance up to 1800 degrees F (982 degrees C), however it is not limited to those applications.

Material Specification: Nickel Alloy, Solution Heat Treated 1950 degrees F (1066 degrees C), Precipitation Hardenable, Vacuum Induction or Consumable Electrode Melted, Rings, Bars, and Forgings, 52.5Ni – 19Cr – 3.0Mo – 5.1Cb – 0.90Ti – 0.50Al – 18Fe. You can find the AMS 5664 specification in Inconel 718 wire alloy.

AMS 5665

Description: Covering a heat and corrosion resistant nickel alloy, the AMS 5665 specification can be found in flash welded rings, bars, forgings, and stock for flash welded rings and forging.

Material Specification: Nickel Alloy, Heat and Corrosion Resistant, Rings, Bars and Forgings, 74Ni – 15.5Cr – 8.0Fe. The AMS 5665 specification is commonly found in Inconel® 600 wire alloy.

AMS 5666

Description: The AMS 5666 specification covers a heat and corrosion resistant nickel alloy that takes the form of extrusions, flash welded rings, bars, forgings, and stock for flash welded rings, or forgings.

Material Specification: Nickel Alloy, Heat and Corrosion Resistant, Annealed, Extrusions, Rings, Bars, and Forgings, 62Ni – 21.5Cr – 9.0Mo – 3.65 (Cb (Nb) + Ta). The AMS 5666 specification can be found in Inconel® 625 wire alloy.

AMS 5667

Description: The AMS 5667 specification covers a nickel alloy that is both heat and corrosion resistant and takes the form of bars, flash welded rings, forgings, and stock for heading, flash welded rings, and forging.

Material Specification: Nickel Alloy, Precipitation Hardenable, Rings, Bars, Forgings, 72Ni – 15.5Cr – 0.95Cb – 2.5Ti – 0.70Al – 7.0Fe. You can normally find the AMS 5667 specification in Inconel® X750 wire alloy.

AMS 5668

Description: The AMS 5668 specification covers a heat and corrosion resistant nickel alloy that is found in flash welded rings, bars, forgings, and stock for heading, flash welded rings, and forgings. It is quite often found in parts such as turbine seals, turbine blades, and bolts that require oxidation and high strength resistance from 1250 to 1500 degrees F (675 to 816 degrees C), but is not limited to these types of applications.

Material Specification: Nickel Alloy, Solution and Precipitation Heat Treated at 2100 degrees F (1149 degrees C), Rings, Bars, Forgings, 72Ni – 15.5Cr – 7.0Fe – 2.5Ti – 1.0(Cb + Ta) – 0.70Al. The AMS 5668 specification can be found in Inconel® x750 wire alloy.

AMS 5670

Description: Covering a heat and corrosion resistant nickel alloy, the AMS 5670 specification can take the form of flash welded rings, bars, forgings, and stock for heading, flash welded rings, and forging. Typically, this specification is used in parts that require heat strength from 800 to 1100 degrees F (427 to 593 degrees C). This is especially true for parts that are welded or formed and then precipitation heat treated in order to develop certain properties, however it is not limited to these applications.

Material Specification: Nickel Alloy, Solution Heat Treated 1800 degrees F (982 degrees C), Precipitation Hardenable, Rings, Bars, Forgings, 72Ni – 15.5Cr – 0.95Cb – 2.5Ti – 0.70Al – 7.0Fe. The AMS 5670 specification is most often found in Inconel® X750 wire alloy.

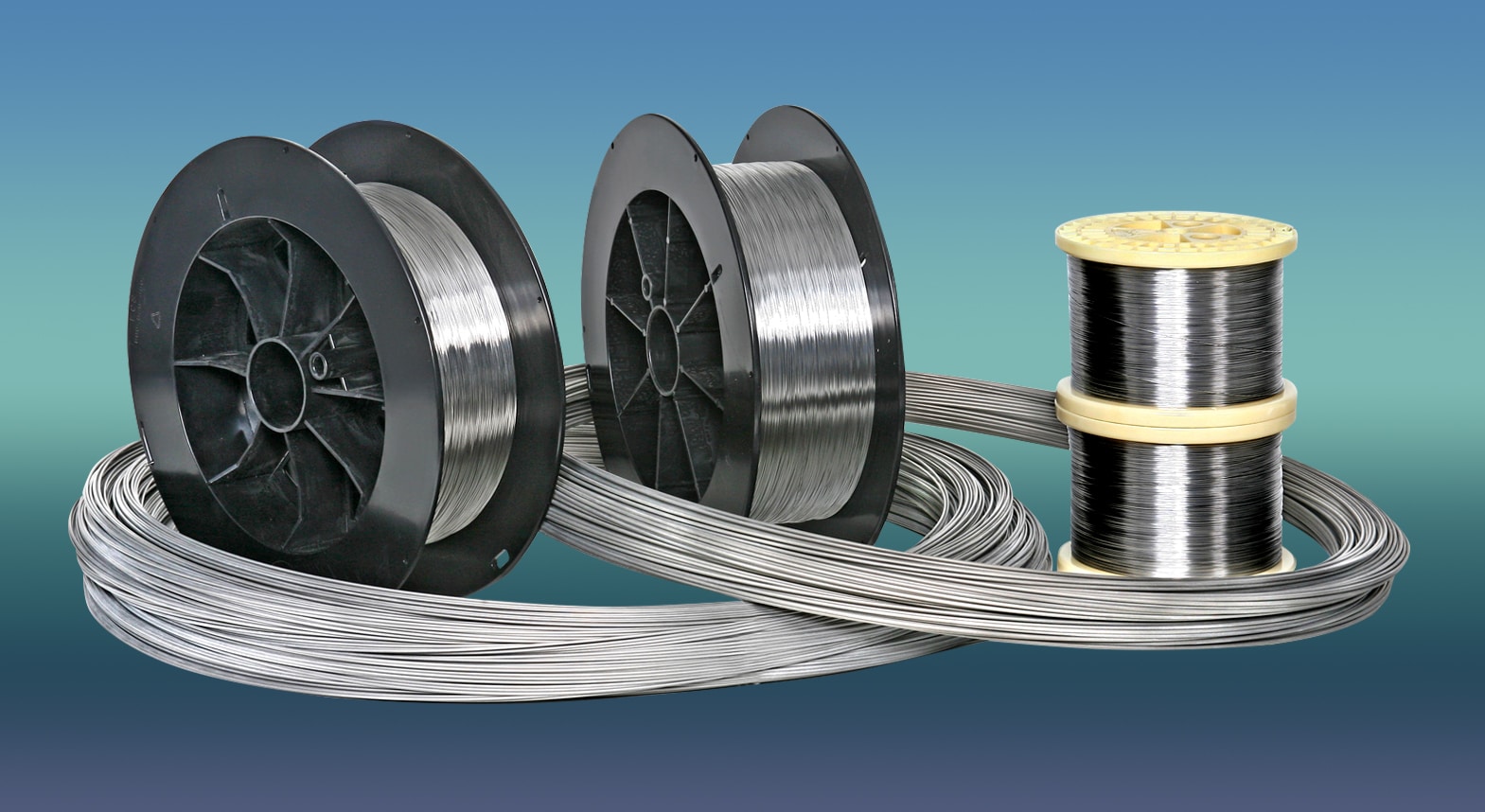

AMS 5687

Description: The AMS 5687 specification covers a nickel alloy that is both heat and corrosion resistant and is in wire form.

Material Specification: Heat and Corrosion Resistant, Nickel Alloy, Annealed, 74NI – 15.5Cr – 8.0Fe. The AMS 5687 specification can be found in Inconel® 600 wire alloy.

AMS 5698

Description: The AMS 5698 specification covers a heat and corrosion resistant nickel alloy that can be found in the form of square, round, and flat wire 0.500 inch (12.70 mm) and under and also in nominal thickness or diameter.

Material Specification: Precipitation Hardenable, No. Temper, Nickel Alloy, Heat and Corrosion Resistant, Wire, 72Ni – 15.5Cr – 0.95Cb – 2.5Ti – 0.70Al – 7.0Fe. The AMS 5698 specification is found in Inconel® X750 wire alloy.

AMS 5699

Description: Covering a heat and corrosion resistant nickel alloy, the AMS 5699 specification can take the form of square, round and flat wire 0.625 inch (15.88 mm) and under and also in nominal thickness and diameter.

Material Specification: Nickel Alloy, Spring Temper, Precipitation Hardenable, Heat and Corrosion. You can most often find the AMS 5699 specification in x750 wire alloy.

AMS 5778

Description: The AMS 5778 specification covers a nickel alloy that is both heat and corrosion resistant that takes the form of welding wire. Typically this wire is used as filler metal for gas tungsten arc or gas metal arc welding of parts that have been fabricated from alloys that share a similar composition. It is not limited to this application however.

Material Specification: Heat and Corrosion Resistant, Nickel Alloy, Welding Wire, 72Ni – 15.5Cr – 1.0Cb(Nb) – 2.4Ti – 0.70Al – 7.0Fe. Normally, the AMS 5778 specification is found in Inconel® X750 wire alloy.

AMS 5832

Description: The AMS 5832 specification covers a nickel alloy that is heat and corrosion resistant and takes the form of welding wire.

Material Specification: Nickel Alloy, Vacuum Induction or Consumable Electrode Melted, Welding Wire, 52.5Ni – 19Cr – 3.0Mo – 5.1Cb(Nb) – 0.90Ti – 0.50Al – 18Fe. The AMS 5832 specification is normally find in Inconel® 718 wire alloy.

AMS 5837

Description: Used for a nickel alloy that is both heat and corrosion resistant, the AMS 5837 specification is normally used as filler metal for gas metal arc or gas tungsten arc welding of parts that are fabricated from alloys that can be similar or dissimilar composition. Its usage is not limited to this application however.

Material Specification: Heat and Corrosion Resistant, Nickel Alloy, Welding Wire, 62Ni – 21.5Cr – 9.0Mo – 3.7Cb(Nb). The AMS 5837 specification can be found in Inconel® 625 wire alloy.

AMS 5869

Description: The AMS 5869 specification often covers a nickel alloy that is heat and corrosion resistant and can be found in strip, plate, or sheet.

Material Specification: Nickel Alloy, Solution Heat Treated, Heat and Corrosion Resistant, Strip, Plate, and Sheet, 62Ni – 21.5Cr – 9.0Mo – 3.7Cb. The AMS 5869 specification can be found in Inconel® 625 strip alloy.

AMS 5870

Description: Covering a nickel alloy that is both heat and corrosion resistant, the AMS 5870 specification can take the form of strip, sheet, or plate.

Material Specification: Nickel Alloy, Solution Heat Treated, Heat and Corrosion Resistant, Strip, Sheet, and Plate, 60.5Ni – 23Cr – 14Fe – 0.35Ti – 1.4Al. The AMS 5870 specification can be found in Inconel® 601 strip alloy.

ASTM B166

Description: The ASTM B166 specification covers nickel-chromium-cobalt-molybdenum alloy (UNS N06617) and nickel-chromium-iron alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045, and N06696). It can take the form of cold-worked and hot-finished rounds, rectangles, hexagons, squares, and cold-worked wire. The material must conform to the composition limits that have been specified in reference materials. The material must be free of injurious imperfections, commercially straight or flat, smooth, and be uniform in condition and quality. The mechanical properties of the alloy such as hardness, elongation, yield strength, and tensile strength is determined by hardness and tension tests.

Material Specification: The ASTM B166 specification is for Nickel-Iron-Chromium-Tungsten alloy (UNS N06674) Rod, Nickel-Chromium-Cobalt-Molybdenum Alloy (UNS N06617), and Nickel-Chromium-Iron Alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045, and N06696). You can typically find the ASTM B166 specification in Inconel® 600 wire alloy.

ASTM B168

Description: The ASTM B168 specification covers sheets, strips, and rolled plates that are made of Nickel-Chromium-Cobalt-Molybdenum alloy (UNS N06617), and Nickel-Chromium-Iron alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045 and N06696). The materials must be prepared, sampled, and then tested in order to examine their conformance to mechanical (Rockwell hardness, elongation, and tensile and yield strengths), dimensional (flatness, squareness, edge, straightness, length, diameter, width, weight, and thickness), grain size, and chemical composition requirements.

Material Specification: The ASTM B168 specification is for Nickel-Iron-Chromium-Tungsten alloy (UNS N06674), Nickel-Chromium-Cobalt-Molybdenum alloy (UNS N06617), and Nickel-Chromium-Iron alloys (UNS N06600, N06601, N06603, N06690, N06693, N06025, N06045, and N06696) Strip, Sheet, and Plate. The ASTM B168 specification is typically found in Inconel® 600 strip alloy.

ASTM B446

Description: The ASTM B446 specification covers Nickel-Chromium-Molybdenum-Tungsten alloy (UNS N06650), Nickel-Chromium-Molybdenum-Silicon alloy (UNS N06219), and Nickel-Chromium-Molybdenum-Columbium (UNS N06625). It can take the form of cold-worked rod or hot-worked rod and bar. The material is required to conform to the chemical composition standards for Silicon, Manganese, Carbon, Nitrogen, Tungsten, Nickel, Copper, Titanium, Aluminum, Iron, Molybdenum, Cobalt, Tantalum, Columbium, Chromium, Sulfur, and Phosphorus. Also, the materials have to live up to standards set for room temperature and heat treatment properties including elongation, yield strength, and tensile strength. The dimensions of the alloy will also be determined including straightness, length, width, thickness, and diameter.

Material Specification: Standard Specifications for Nickel-Chromium-Molybdenum-Tungsten alloy (UNS N06650), Nickel-Chromium-Molybdenum-Silicon alloy (UNS N06219), and Nickel-Chromium-Molybdenum-Columbium alloy (UNS N06625). The ASTM B446 specification is found in Inconel® 625 wire alloy.

ASTM B637

Description: The ASTM B637 specification covers cold and hot-worked precipitation hardenable nickel alloy bar, rod, forgings, and forging stock for high temperature applications. Each piece undergoes chemical analysis in order to make sure that they conform to requirements in Nickel, Copper, Iron, Boron, Zirconium, Aluminum, Titanium, Tantalum, Columbium, Molybdenum, Cobalt, Chromium, Sulfur, Phosphorus, Silicon, Manganese, and Carbon. Also, each piece follows recommended precipitation hardening treatments, stabilizing treatments, solution treatments, and annealing treatments. Stress-rupture testing, hardness testing, and tension testing is also performed in order to make sure each piece complies with standards regarding elongation, reduction in area, Brinell hardness, tensile strength, and yield strength.

Material Specification: Cold Worked and Precipitation Hardening Nickel Alloy Bars, Forging Stock, and Forgings for High or Moderate Temperatures. ASTM B637 specifications are most often found in Inconel® X750 wire alloy.

ASTM B670

Description: Covering rolled precipitation hardening Nickel alloy (UNS N07718), the ASTM B670 specification is found in strip, sheet, and plate forms that is in the annealed condition for high-temperature applications. All pieces have to conform to regulations regarding the chemicals such as Boron, Nickel, Copper, Iron, Aluminum, Titanium, Tantalum, Niobium, Columbium, Molybdenum, Cobalt, Chromium, Sulfur, Phosphorus, Silicon, Manganese, and Carbon. Once the materials have undergone precipitation hardening, they must conform to requirements in mechanical properties such as elongation, yield strength, and tensile strength. All stress-rupture tests are performed in accordance to ASTM documentation.

Material Specification: The ASTM B670 specification covers Precipitation-Hardening Nickel alloy (UNS N07718) for Strip, Sheet, and Plate, in High-Temperature Services. The ASTM B670 specification can be found in Inconel® 718 strip alloy.

AWS A5.14

Description: The AWS A5.14 specification covers both Nickel and Nickel alloy in rods and welding electrodes. The major topics that are covered are application guidelines, packaging, testing, and general requirements. Each piece independently makes use of the US Customary Units, and International System of Units (SI).

Material Specifications: Chemical Compositions for 50 Nickel and Nickel alloys, Rods, Welding Electrodes. AWS A5.14 specifications are commonly found in Inconel® 718 wire alloy.

INCONEL® is a registered trademark of the Special Metals Corporation group of companies.